IML Inspection System

Feature

-

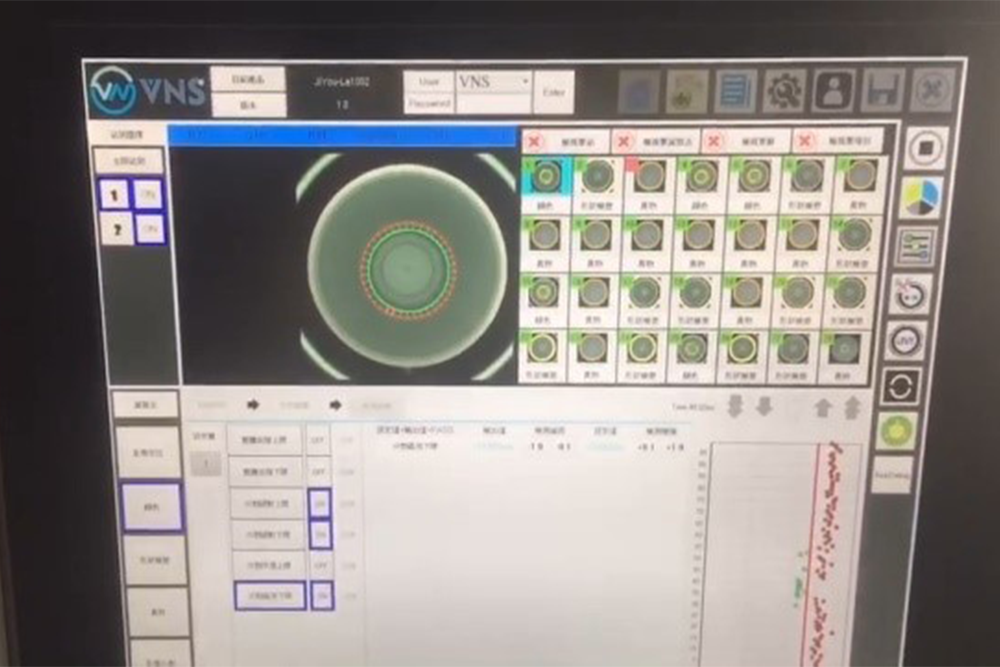

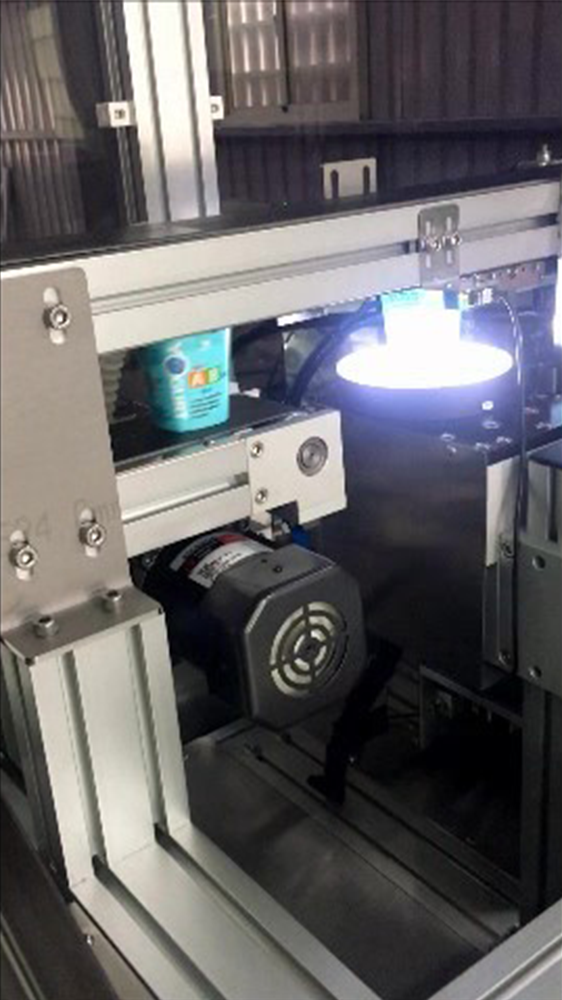

Easy Control: PC-based control system is equipped with HMI touch panel.

-

Quick Adjustment: Quickly set up through auto-learning system and intelligent parameter.

-

Multi Application: Automated machine learning system. System could be set up and change easily to fit various production line.

-

Effective productivity: Enables to check more than 300pcs/ min.

-

High Flexibility: The system is compatible with multiple cameras to improve flexibility and quick setting.

-

Customized Manufacture: System has high and low inspecting speed version. Enables to buy the ideal system with best price.

- Quality Monitor:Enables to report the statistical data to increase the yield.

- IML inspection system is used to check after labeling. The main inspected algorithm includes foreign matter, stain, color, size, circularity, label stitching, missing label, crooked label, double label, label is drilled into injection goods.

- Defect Determination Adjustment: Every defect could be adjusted its accuracy individually.

- Statics Data: Enables to classify defective type and report to the production line to apply modification based on the defects.

- Machine Learning: Every new product could be set up quickly through machine learning system.

- Product Management: The adjusted parameter value could be stored into database and called out for using.

- Event Recorder: The operating behavior could be recorded by 24 hours monitoring that could trace back and modify the machine failures.

| Model No. |

Product Name |

Max. Capacity (Cycle Time) |

| VML100 | IML Inspection Machine without Loading and Stacking Device | 8 Cav. 8 Sec. |

| VML200 | IML Inspection Machine with Loading and Stacking Device | 8 Cav. 8 Sec. |

| Inspection Accuracy | |

| Item |

Defects Determination Standard |

| Black Spot Check | Objective diameter > 0.5mm |

| Foreign Matter Check | Objective dimeter > 0.5mm |

| Integrity Check | Crack diameter > 0.5mm |

| Stain Check | Color difference > 5 Gray Level |

| Alignment Check | Crook degree> 2 degree |

| Circularity Check | Diameter difference > 0.5mm |

| Dimeter Check | Diameter difference > 0.5mm |

| Color Check | Color difference > 1 Gray Level |

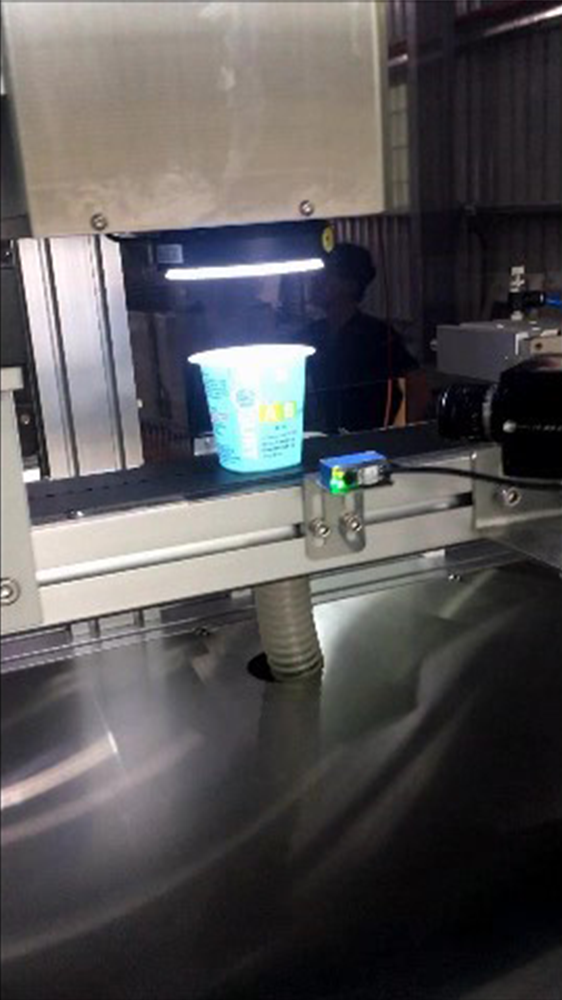

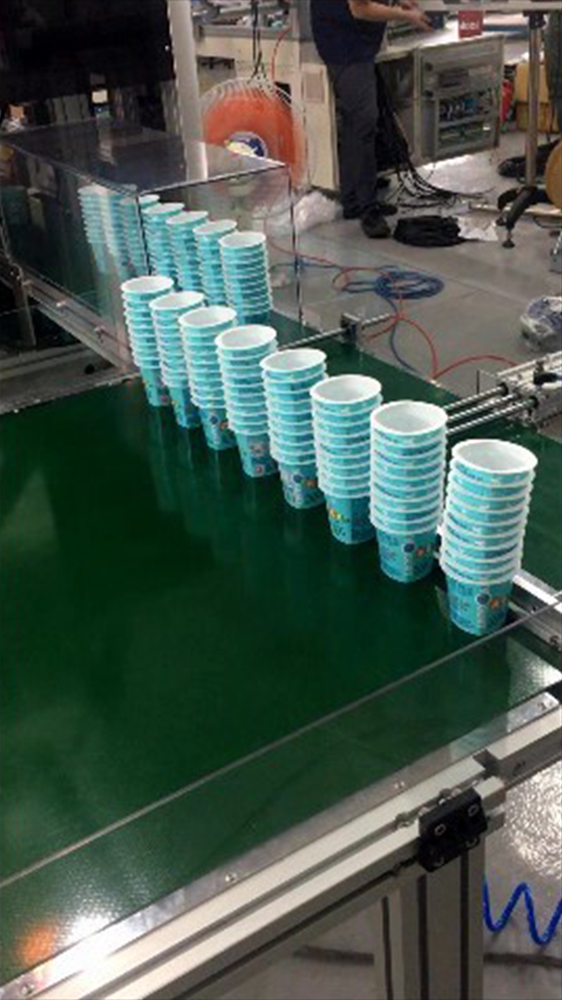

Yogurt Cup Inspection-The inspection system connects with customer’s production line directly. After cup manufacturing, the robot will load the cup, cup will go into vision system to do quality check. After rejecting the defects, the good cup will be re- to facilitate packing process, defects items including inside/outside contamination, foreign matter, broken, bottom burr.

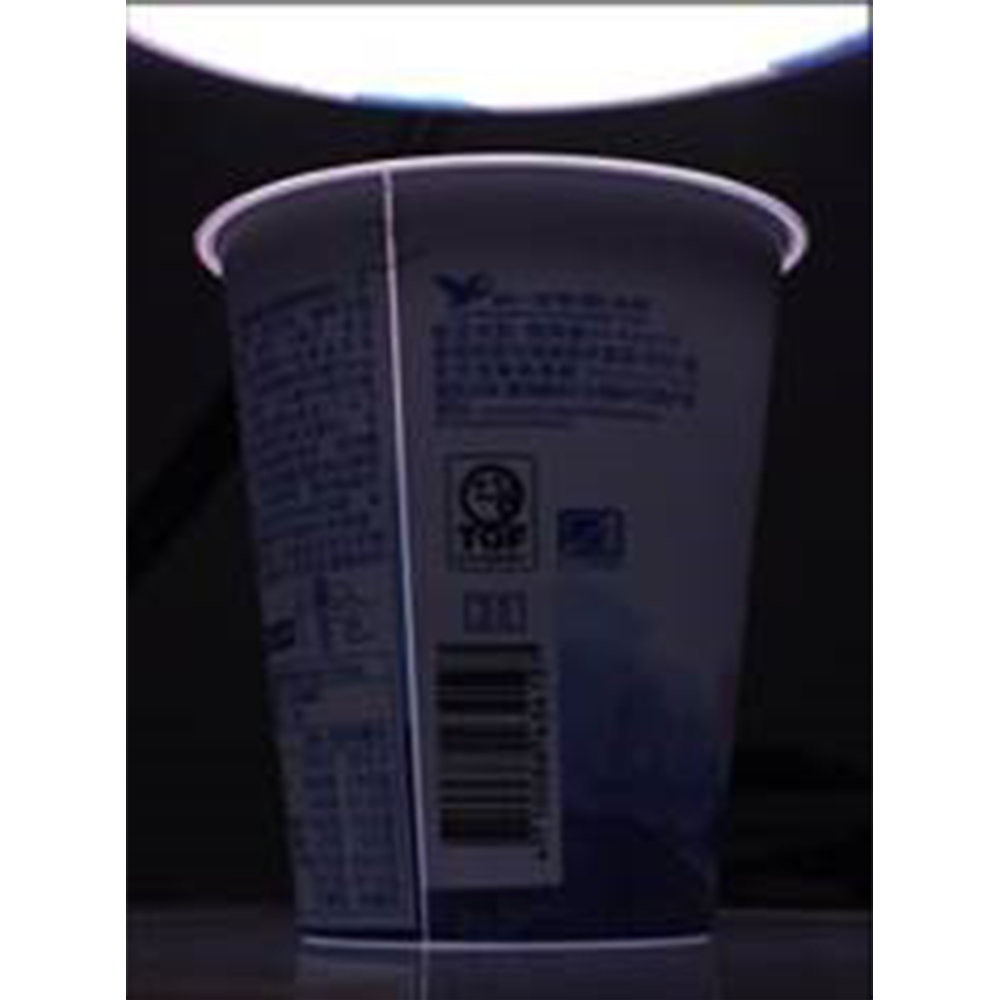

Coffee Cup Inspection-Through special mechanism design and optical module, the cup inside and outside defects can be detected comprehensively and accurately. The inspection items include contamination, foreign matter, broken, deformation, label side stitches, label printing, integrity, and side seam.